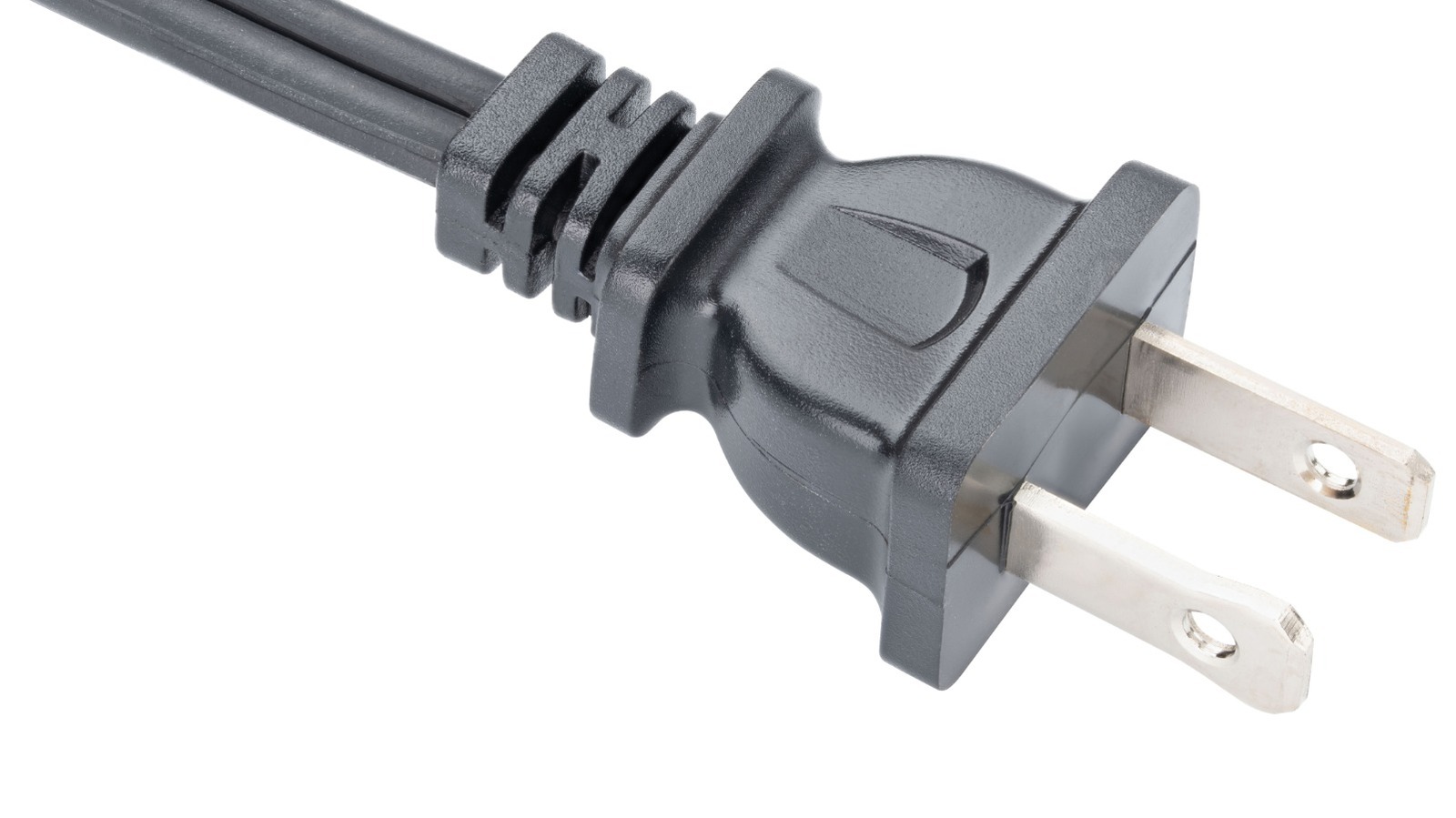

Understanding the Purpose of Holes in Electrical Plug Prongs

What Are The Holes In Electrical Plug Prongs For? - SlashGear 🔗

Holes in the prongs of electrical plugs, specifically in the US standard types A and B, serve primarily a manufacturing purpose rather than a functional one. While many believe these holes help secure the plug in a socket, they actually do not contribute to its stability, which relies on friction alone. According to the National Electrical Manufacturers Association (NEMA), these holes are optional and were created to aid in the manufacturing process, such as holding prongs in place during molding. Additionally, people have found practical uses for these holes, like attaching labels for out-of-order appliances or reminders for safety equipment when using tools.

- The holes in plug prongs are primarily for manufacturing purposes.

- They do not help keep plugs secured in sockets, which rely on friction.

- Creative uses include labeling non-functional appliances and safety reminders.

What is the main purpose of the holes in electrical plug prongs?

The holes are primarily for manufacturing purposes, helping to hold the prongs in place during the molding of the plastic part of the plug.

Do the holes in plugs help keep them secure in wall sockets?

No, the holes do not provide security; plugs stay in place due to friction with the socket.

How can people creatively use the holes in plug prongs?

People use the holes to attach labels indicating that appliances are out of order or to remind themselves to wear safety equipment when using tools.